Wafer Rolls

Master wafer perfection with production systems designed for delicate layer formation, precise rolling mechanics, and versatile shape capabilities while maintaining ideal crispness.

Wafer Rolls

Delicate texture meets manufacturing precision in our wafer roll systems. Our technology creates perfect batter consistency, ensures uniform baking, and executes flawless rolling operations for everything from hollow cylinders to filled sticks.

Advanced temperature control and precision timing deliver consistently crisp wafers with perfect layer separation and exceptional eating experience. Each product maintains structural integrity while providing the delicate crunch consumers love. Our forming systems accommodate diverse shapes while maintaining the ideal thickness for perfect crispness.

Product Categories

Hallow Wafer Line

Wafer Sticks

Wafer Roll Double Color

Get a Quote

Discover precision-engineered food machinery, crafted to meet specific manufacturing requirements.

Need more help?

We provide customized solutions for efficient, reliable, and innovative machinery to enhance your production process.

+91 9363533799

info@icubemachinery.co.in

Find Machinery Engineered with Innovation to Match Your Product Requirements.

The ICUBE Process

Dough Preparation

Precise measurement and blending of ingredients create a smooth, homogenous dough essential for achieving consistent texture and structure. Proper dough preparation establishes a reliable base, enhancing quality and ensuring uniformity throughout subsequent processes, including baking and shaping, to meet desired product standards.

Baking

The prepared dough undergoes controlled baking within specialized ovens, achieving optimal crispness and uniform coloration. Maintaining consistent temperature and timing is critical for ensuring even baking, structural integrity, and desired texture. Proper baking contributes to the wafer rolls’ distinct crunch and readiness for shaping.

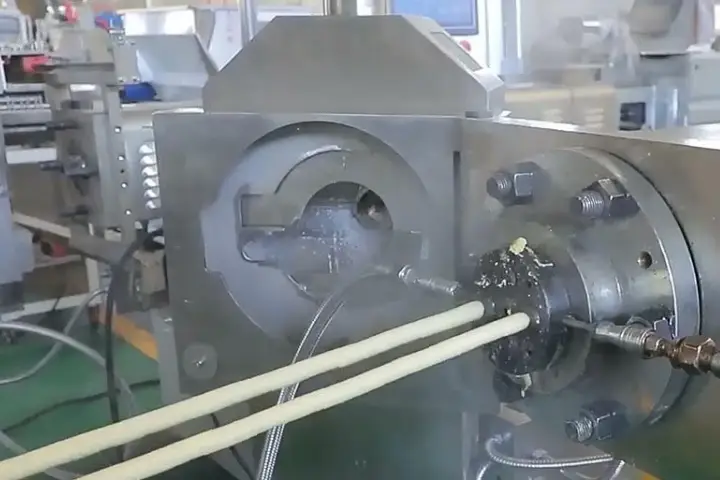

Rolling & Shaping

Freshly baked wafers are expertly rolled into cylindrical shapes with precision timing to ensure structural integrity and uniformity. This critical step enhances product appearance, texture, and suitability for various fillings or coatings, ensuring consistency across batches and enhancing overall quality.

Cooling

Freshly rolled wafers undergo controlled cooling to stabilize their structure and enhance crispness. This essential step allows the formed shapes to set properly while reducing moisture content to the ideal level. Precise temperature management during cooling ensures optimal texture development and prepares the product for quality inspection and packaging.

Packaging

Wafer rolls are securely packed to maintain freshness, crispness, and structural integrity. Effective packaging protects the product from external factors such as moisture, contamination, and breakage, enhancing shelf life and preserving the desired quality throughout storage and distribution.